Newman Smith High School Robotics Team One Team 07-0071 |

|||||||||

|

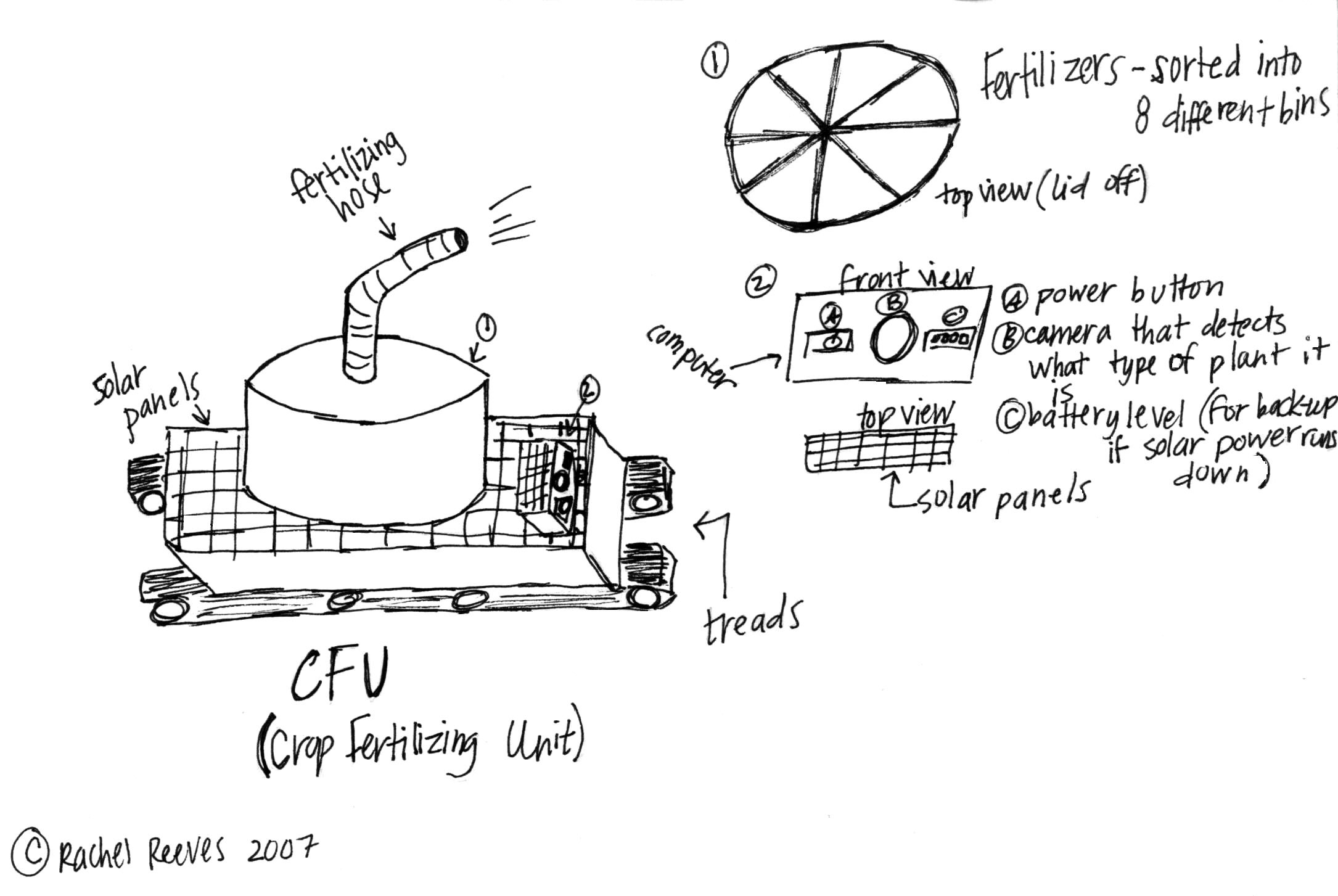

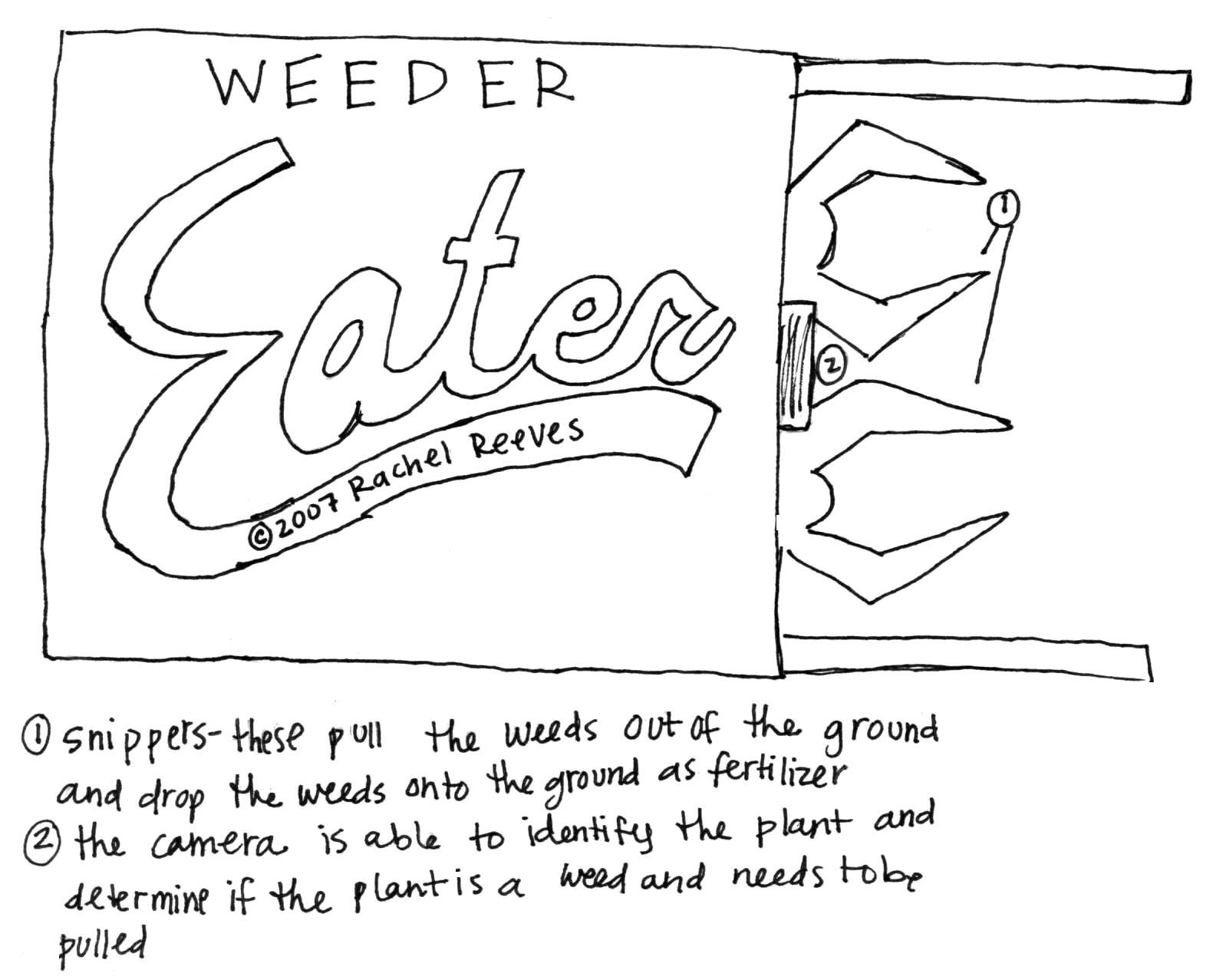

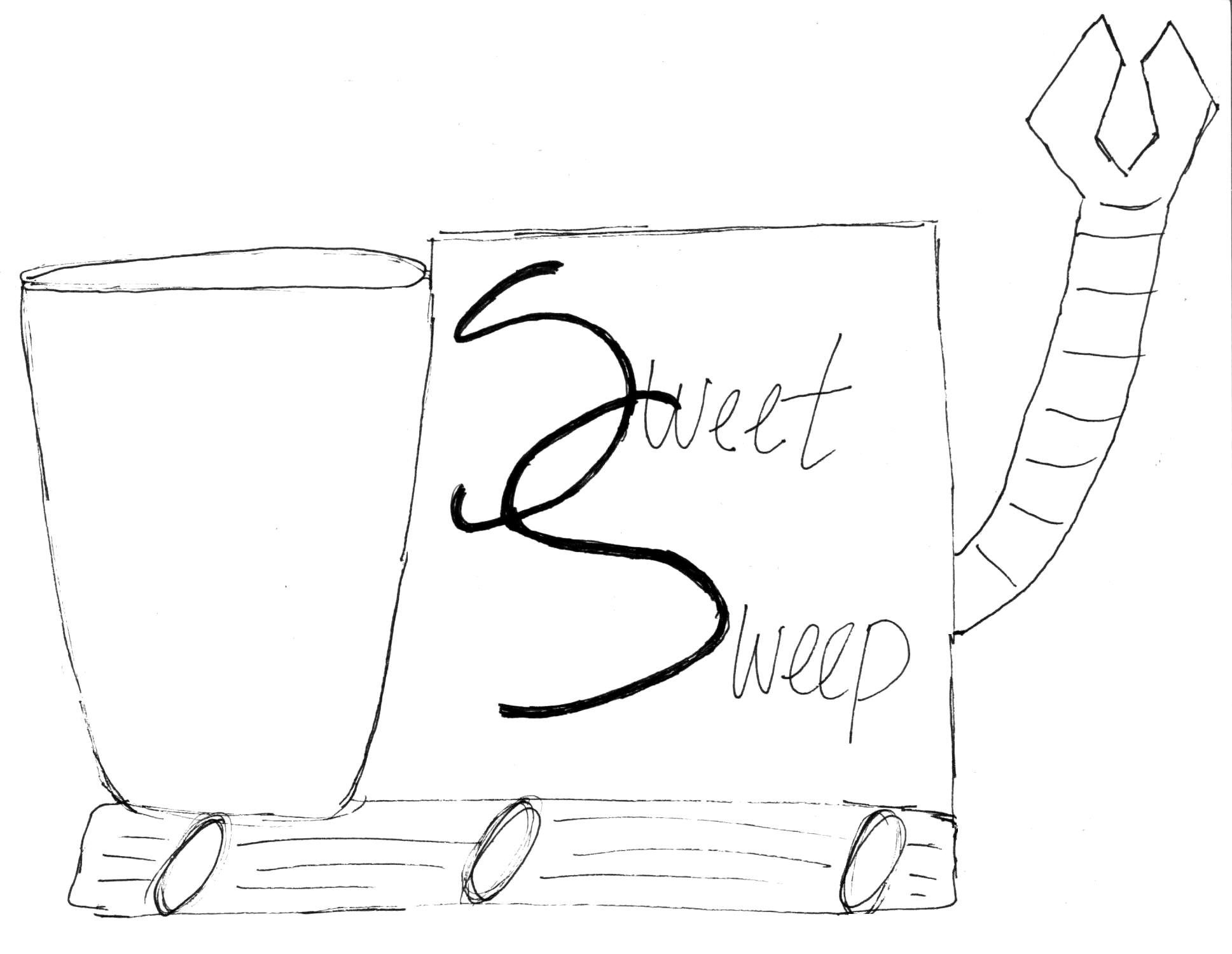

Our Solutions Our goal was to create robots that accomplish three things: cut down on the farmer's workload, make the cost of running a farm easier to bear, and take better care of the environment than current methods to perform the same job. Each robot was created to fix a specific problem. The first robot, the Crop Fertilizing Unit, was made to provide different plants with the type of fertilizer that they need. The next robot we designed, the Weeder Eater, picks weeds, as well as any plants that do not belong in the field the robot is in. Our final robot, the Sweet Sweep, was invented to pick ripe fruit, which can be a very monotonous task for farmers. Problem: Different plants need different fertilizers Solution: The CFU The CFU, or Crop Fertilizing Unit, has eight sections that can hold eight different types of fertilizers. This robot costs only $1500, and each CFU can cover up to 11 acres a day. This saves the farmer a lot of money in labor costs. The robot is programmed to know which fertilizer is in each section. The lid on top of the fertilizing container can be removed for easy access to the fertilizer for refilling and maintenance purposes. The CFU fertilizes the crops using a fertilizing hose that has a rotation of 360 degrees, enabling it to spray plants wherever they happen to be. The camera on the robot takes a picture of the plant and the computer processes the photo to determine what the plant is. The robot then sprays the plant with a certain fertilizer, made specifically for that plant. The CFU is powered by solar panels that cover the top of the robot, and has a back-up battery for cloudy days or when the solar panels break down. On the front of the robot there is a battery reader which lets the farmer know how much battery is left. The CFU uses a GPS to navigate and help the farmer keep track of its location. The farmer can program the robot so that it knows approximately where each plant should be. Using his computer, the farmer can "tell" the robot which fields he wants fertilized on a particular day. The CFU decreases the amount of excess fertilizer sprayed on plants, decreasing runoff. Problem: Weeding takes a lot of manpower Solution: The Weeder Eater The Weeder Eater is a convenient and easy way to pick weeds without picking "good" plants. This small robot costs less than $1000, and a single Weeder Eater covers as much as 18 acres a day. The Weeder Eater cuts down on labor costs, monotonous work, and the number of unpicked weeds and mistakenly picked crops. It uses a camera, which feeds its image into a computer that scans it against the crop that is supposed to be in the field that the Weeder Eater is in. Once a plant has been identified as a weed, it is pulled out of the ground by the snippers. A weed is defined as any plant that is not supposed to be in the field. For example, if there are carrots in a corn field, the Weeder Eater would pull the carrots up, since they aren't supposed to be in that field. After the snippers pull the weed, they drop it back onto the ground to act as extra (free!) fertilizer. The snippers have a 70% success rate with pulling weeds up by their roots, so that they are less likely to grow back. When the Weeder Eater is done for the day, it returns to its base station to recharge its battery, which has a 9.2 hour life so that it can last through the day. This robot increases the overall crop yield, and, when run through a field right before the CFU, decreases excess fertilizer usage. Problem: Picking fruit is a tedious task Solution: The Sweet Sweep The Sweet Sweep is a fruit-picking robot that operates using a GPS, which helps the robot know where it is and what type of fruit is in that area. This robot costs between $2200 and $2800, depending on the basket size picked, and can pick up to 3500 apples a day. Sweet Sweep uses a vision system located inside the claw to find fruit that is ripe enough to pick, and then uses its claws to collect the fruit and deposit it into the basket without bruising the fruit. The lid to the basket opens whenever the claw is about to place fruit into the basket, and then closes when the claw is finished depositing the fruit. In the basket, the fruit is misted every five minutes with cold water, so that the fruit inside stays fresh. When the basket is full, the Sweet Sweep returns to the docking station where it empties the basket and heads out again. The Sweet Sweep is powered by a combination of solar panels (on top of the robot) and a battery. This robot has many other sensors, including one inside the basket where the misting mechanism will not spray when it senses that the basket is empty. The farmer on duty can monitor the robot from any device with internet access, so that he knows where the robot is and how much fruit it has picked. The Sweet Sweep returns to the same field every other day, so that it can cover as much ground as possible while picking as much fruit as possible. This robot takes over the monotonous, slow work of fruit-pickers, and increases the number of ripe pieces of fruit picked at the same time. |

||||||||