07-0022 Introduction History Current Developments Future Bibliography Acknowledgments About Us |

07-0022 Introduction History Current Developments Future Bibliography Acknowledgments About Us |

Unlike

large tractors, ag robots won't compact the soil as they move through the

rows of crops because of their light weight. Cameras are presently

used to detect weeds but larger sensors to detect crop stress and disease,

insect activity sensors, and soil sensors still need to be developed.

Once the sensors are developed, the next step will be to develop ag robots

that can weed, spray precise amounts of chemicals, and plant. The

goal is to eventually have an army of robots that can perform all farming

activities through a system of sensors, wireless communication, and data

managing software.[13]

Unlike

large tractors, ag robots won't compact the soil as they move through the

rows of crops because of their light weight. Cameras are presently

used to detect weeds but larger sensors to detect crop stress and disease,

insect activity sensors, and soil sensors still need to be developed.

Once the sensors are developed, the next step will be to develop ag robots

that can weed, spray precise amounts of chemicals, and plant. The

goal is to eventually have an army of robots that can perform all farming

activities through a system of sensors, wireless communication, and data

managing software.[13]

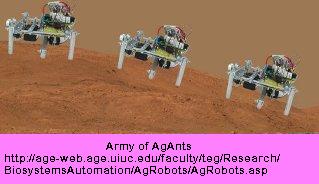

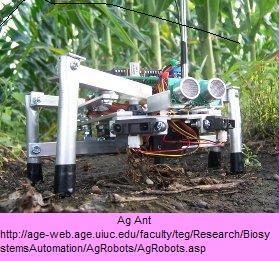

Tony Grift of the University of Illinois is developing an ag robot called the Ag Ant. The Ag Ant is a fully autonomous robot that will eventually work as part of a group of other Ag Ants to detect weeds, spray pesticides, and do soil tests. When an Ag Ant detects a weed, it will be able to communicate to the other Ag Ants to come and help destroy it. The other Ag Ants will find the calling robot by GPS technology. An Ag Ant will cost roughly $150 so it will be affordable to buy an army of them.[11]

A $7,000 Ag Bo designed by Yoshi Nagasaka and Tony Grift uses a laser scanner

to guide it along rows of crops. Its small wheels provide better

performance on dry soil than on mud. It can be remotely controlled

and has fully independent steering.[3][11][13]

A $7,000 Ag Bo designed by Yoshi Nagasaka and Tony Grift uses a laser scanner

to guide it along rows of crops. Its small wheels provide better

performance on dry soil than on mud. It can be remotely controlled

and has fully independent steering.[3][11][13]

![]()

Another robot is the AgTracker, which can turn well in muddy soil because of skid steering. It is powered by two motors and has 8 infrared sensors, ultrasound sensors, and an electronic compass. It is controlled by a BasicTOM40-M micro controller. The cost is about $500.[3][11][13]

Current work is being done to perfect the navigation system. Once that is accomplished, work will begin on developing the sensor feedback system, having the ag robots perform field operations, and combining a wireless communication system with either the GPS or Galileo positioning system.