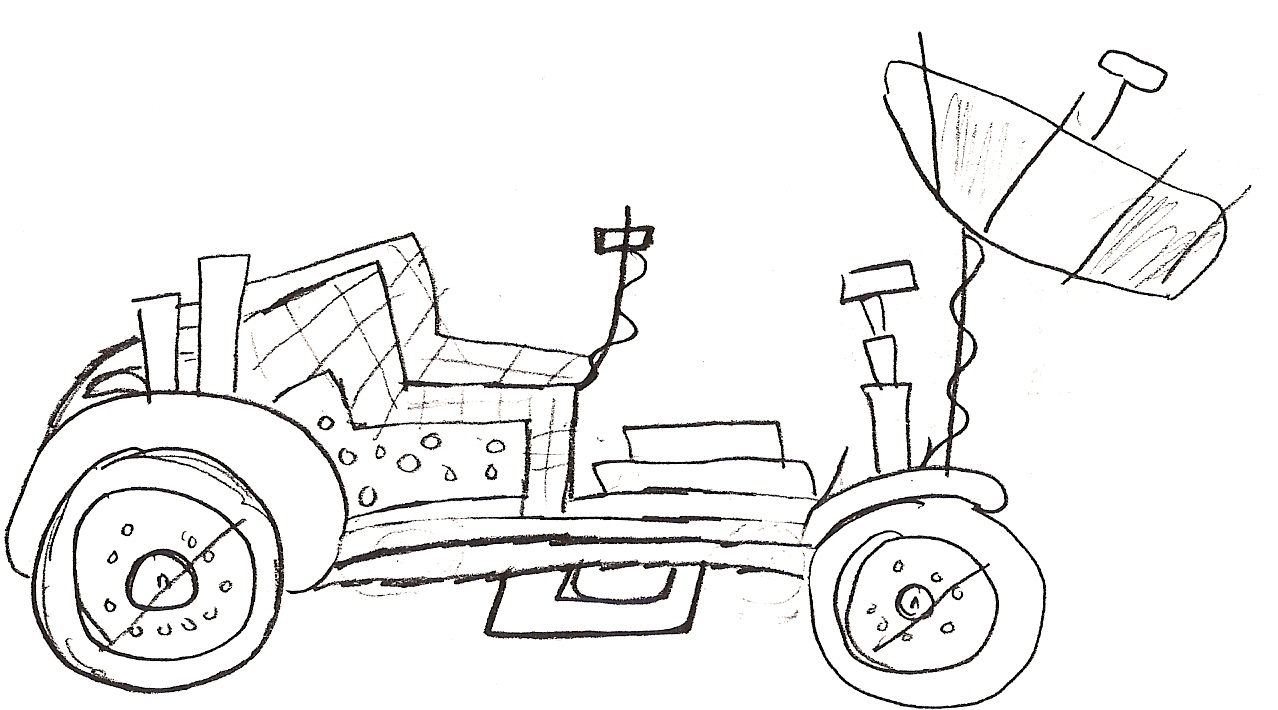

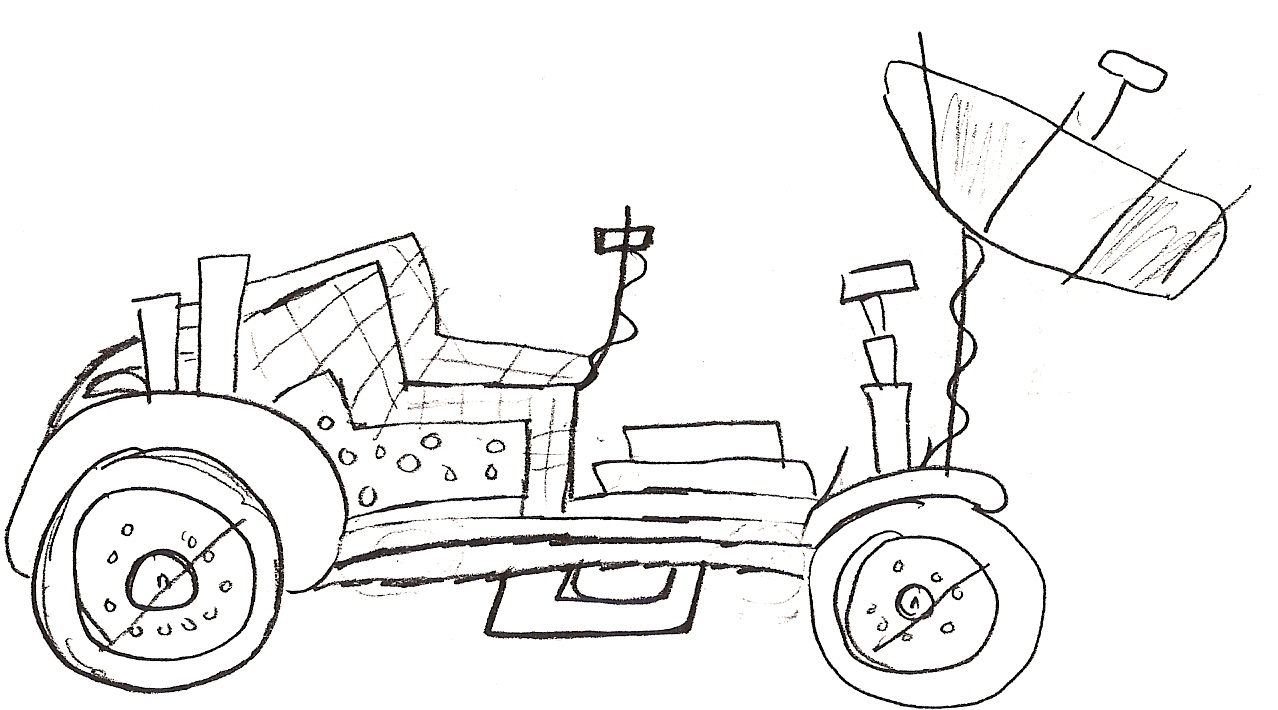

Rover Design

2.1.1 Tires - The rover must be designed to have a degree of "street legality", so tires should be of conventional design. All weather / off road tires are preferable. Multiple tires on a single axle are permissible. Size of tires will depend on the vehicle size. However, tire size and vehicle clearance should be at least comparable to that for standard off road vehicles. Sport Utility Vehicles are not classified as off road vehicles for this analysis.

2.1.2 Suspension - Independent strut suspension systems are considered best for this application. Standard heavy duty shock absorbers, designed for off road use are desirable. Shock systems are best if filled with air. Hydraulic systems will also be considered. Suspension systems for vehicles designed for extensive off road activity should be considered, if not fully integrated with a modified chassis.

2.1.3 Chassis / Frame - The best approach is to obtain the frame of an existing vehicle. The frame type will be a function of the loaded weight and dimensions of the crew compartment.

2.1.4 Pressurized envelope / Body - This is the structure that simulates the pressurized crew compartment. It should look and function as though it is a pressurized envelope, but will not be pressurized in this iteration. Depending on whether it is designed for a hot or cold climate (your choice) it must have sufficient heating and / or air conditioning to enable it to function in either environment. It must have sufficient living space to accommodate a crew of 2-3 for a 1 week mission. As a general guideline, it is currently believed that at least 2m^3 per crew member is required for this application.

2.1.5 Pressure ports - This rover design will not have an airlock. Airlocks are very systems intensive and add considerable mass. It is assumed EVA will occur by reducing pressure in the entire rover (the less volume in the rover, the better - see above). Another option is that EVA suits may be considered docked to a "suit port", in which the crew member enters the suit directly from the rover interior without depressurizing the interior. As an option, a second port may be included that enables direct connection to the hub. The docking port must be 1.67m above grade (measured from the inside bottom of the hatch frame). The docking port must be at the front or rear of the vehicle. Consequently, the rover will have at least one pressure port, which may be a suit port, with a possible second for hub docking.

2.2 Power plant - The following describes desired thrust characteristics and associated systems:

2.2.1 Engine - Use of gasoline or diesel engines, integrated with an existing vehicle is the most economical option. Since the typical off - road speed is 20mph (32.2 km/hour), consideration should be given to an ability to operate at low gear for long periods of time. Such an arrangement would allow higher speed road operation when not in a simulation mode. While exotic thrust systems are not necessary in an analog vehicle, proposals containing unique systems will be considered. Whatever system is chosen, it must be capable of either extreme cold or hot weather (operation one of the two.)

2.2.2 Electrical system - A conventional electrical system, designed for use in cold climates is best, but not necessary, if optimized for warm weather (see 3.4.2.3). Typical systems will use conventional 12V lead acid batteries with no less than 500-600 "cold cranking amps". The rover may be designed such that power for all systems is provided by the main power plant (the engine). This requirement assumes that the engine may need to be in operation continuously for a 1 week period. A diesel engine may be best suited for this application. Use of an "auxiliary power unit (APU)" to provide power for critical "life support" when the main plant is not operating, will be considered, as an option. The APU may be a gas or diesel generator.

2.2.3 Fuel - The rover must carry enough fuel to enable one - way travel of at least 200 miles (320 km).

2.2.4 Speed! - The rover must be capable of at least 20 mph (32km/hr) over "easy terrain".

2.3 External fittings - The following describes systems required to support exploration activity that may be integrated with the exterior structure of the rover.

2.3.1 Crane - Optional. A crane may be provided to assist in lifting of rock boxes or EVA equipment. It should be simple in design and allow operation from inside or out of the rover. It should have a clear radius of reach of at least 180 degrees around the rover.

2.3.2 Winch -Recommended. An electric or manual winch may be included. Its primary function will be to assist in removal of the rover from mud or other difficult categories of terrain. It may also help extract other vehicles or be used in movement of heavy equipment.

2.3.3 Detachable tools - Optional. This is analogous to the various blades, grading devices and drills that can be fitted to a "Bob Cat" light construction vehicle. If it is desired to pursue this option, the tools, attachment locations and a place for cargo must be included in the design.

2.3.4 Sample stowage - Required. This is best if it is an open rack with a means of securing rock / sample boxes. An adequate analog for a rock box is a "Playmate Cooler" ice chest. Accommodation for no less than 6 boxes should be provided. The rack should be easily accessible by a person standing on grade.

2.3.5 Sample pressure port - Optional. This would be a pressure port opening directly from the sample stowage area. It would enable removal of samples from a rock box and transfer directly into a glove box that would be accessed by crew members when inside the rover. A possible method for use may be that the crew members remove rocks from the box while still suited, place them into the port, close it and enter the rover. After completing the re - pressurization procedure, they could access the sample in a glove box in the rover. This method assumes the sample is kept in its immediate surroundings environment while it is examined. As an alternative, rocks may simply be moved directly into the rover and physically examined.

2.3.6 EVA equipment stowage - Required. This will be 1-2 boxes for containment of EVA tools (shovels, rakes, drills, etc.). A good analog may be the tool boxes commonly used on pick-up trucks. Though, the box for the rover may need to be narrower. To determine overall size, it is recommended that research be conducted regarding the tools used for the lunar missions. Much of this information is obtainable via NASA websites. The box must be accessible by a person standing on grade.

2.3.7 Manipulators - Optional. This enables collection of samples from inside the rover. Manipulators must have access to rock boxes in the stowed condition. The manipulator work station must be separate from the driverís station.

2.3.8 Tow bar connect - Optional. This will be a hard point located on the rover frame at the front or back (or both) of the vehicle, that enables towing or pushing of other vehicles of comparable size. It may also be used to tow a trailer. Trailers may be included in the design, and may be used to carry fuel, additional power systems, etc. But, they may only carry consumables that extend range beyond the design constraints. All consumables to meet the design constraints must be carried in and on the vehicle frame.

2.3.9 Communications - Required. The rover must have mounting points for radio antennas for communications with EVA personnel and the Mars base. The nature of the precise communication system may be proposed by the individual teams, subject to approval by the review group.

2.4 Internal fittings - The following describes internal furnishings and systems necessary to support the crew.

2.4.1 Life Support System

2.4.1.1 Waste disposal - A means of containing and storing liquid and solid human waste for one week must be provided in the rover crew compartment. This may be as simple as containment for storage bags (that could be attached to the outside of the rover) or chemical marine toilets. A means must be provided to conceal the waste disposal area when it is in use. Non - human waste products should be retained in a container that mounts to the exterior of the rover.

2.4.1.2 Water supply - Water must be supplied for drinking, food, rehydration and dish washing for each crew member for 1 week duration. Water allowance must also be provided for basic hygiene - brushing teeth and "field hygiene" bathing (like a sponge bath). It is recommended that water not be used for waste flushing. A means or system for containing waste water, not containing human waste products, should also be provided.

2.4.1.3 Heating, ventilation and air conditioning - Systems must be provided that enable heating and cooling for either desert or polar environments. For project design purposes we will consider the temperature range to be either +70 degrees F to +120 degrees F or +70 degrees F to -50 (your choice). This is comparable to Death Valley in the summer or Doe, Antarctica in the summer. The designed vehicle should be optimized for one of the two environments. A means of rapidly ventilating the crew compartment should also be considered.

2.4.2 Furnishings - The crew compartment must contain seating, sleeping, personal stowage and eating accommodations for all crew members. Depending on the design, these may be individual areas (separate dining / sleeping areas) or they may be combined. Convertible compartments with combined functions will be considered best for this application. The crew compartment must have adequate general illumination and task lighting for work stations. A means of providing acoustic privacy between work and sleep areas is desirable. It is strongly recommended that rover teams obtain and / or consult human factors design references when designing the crew compartment.

2.4.2.1 Food Preparation - Adequate food storage and preparation facilities must be provided to support a 1 week field trip.

2.4.3 EVA systems - A space must be provided for donning / doffing EVA suits in the crew compartment and storage of the suits. This requirement is relaxed if suit ports are used - minimal space will be required for donning / doffing EVA suit inner clothing prior to entering the suit, through the port. If manipulator arms are used, a work station, other than the driverís station must be provided.

2.4.4 Science systems - A work station for sample examination and analysis must be provided inside the crew compartment. For sizing purposes it must be able support a lap top with enough additional area for writing implements and papers. Allow for a stowage locker inside the rover with 0.5m^3 of volume for securing scientific instruments when not in use.

2.4.5 Vehicle control - A driver's station with excellent visibility must be provided. This station will have all controls and indicators necessary to control the vehicle and monitor systems. A secondary set of controls next to the main station are an option. If a docking port is used (see 2.1.5), and it is located at the rear of the vehicle, an additional control station must be provided that controls steering, power and braking. The ability to remotely control the rover is a very desirable option. This would enable relocation of the vehicle if all crew members were on EVA. Another option is autonomous operation enabling return of the vehicle to a designated point if the crew were incapacitated.

3.0 Performance Requirements - The following are the rover's desired performance characteristics:

3.1 Speed - 20 miles / hour over moderate terrain.

3.2 Range - 200 mile one - way trip. It must be remembered that the mission of this vehicle mandates that it stop and start with high frequency, with its engine or APU running constantly for 1 week. Consequently, most fuel will be dedicated to running systems and not attaining the maximum range.

3.3 Vehicle mass - 1500kg (3333.3lb). This is dry mass. The purpose of this limit is to see if this is a realistic target mass. Contrary findings, if rigorously supported, will be considered.

3.4 Terrain - Must have off - road clearance and capability and ability to negotiate roof terrain while maintaining speeds of at least 5 mph.

3.5 Logistics - Must be transportable via C-130 (Lockheed L-100) Hercules. This mandates a packed width of 9'-0" (2.7m), height of 8'-6" (2.6m) and length of no more than 24'-0" (7.3m). Means of folding, or use of inflatable systems may definitely be considered.

< Home > < Our Goal > < Landing Site > < Terrain >

< Delivery Module > < Communications > < Bibliography >

11. The Mars Society

http://www.marssociety.org/portal/c/pressurizedRover/RoverContestSpecifications