Information about the milking is sent to a computer for analysis. The machine can keep track of how much milk, the milk flow and milking time not only for each cow but also for each of the cow’s teats. This information can be used to tell how healthy the cow is and indicate disease. After the cow is milked, the robotic arm moves away and then applies a disinfectant solution to the cow’s underside. The cow is then allowed to leave. The VMS then cleans itself before another cow is allowed to enter the system. There are several advantages to the VMS. The cows can decide to be milked more than the twice a day routine used in most dairies. Some dairies have seen an increase in milk production. Dairy farmers are freed up to do other things around the farm instead of having to be locked into the twice a day routine. [19]

Back to Current State

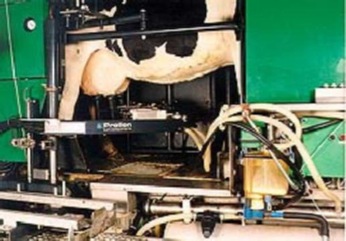

Many companies have developed Voluntary Milking Systems (VMS) for automated cow milking. How does it work? Cows can decide that they want to be milked and walk into the milking parlor. A tag on the cow which contains electronic information about the cow is read by the computer, and if enough time has passed since the cow’s last milking, the cow is allowed to enter. First the cow is given a food supplement. While it is eating, a robotic arm moves under the cow and uses lasers and photo sensors to find the teats. The computer has images of each cow’s teats and how they are positioned. This helps the laser to find each teat and guide the robotic arm. Each teat is cleaned and then vacuum milking cups are attached.

Variation:

Some robotic milking systems have installed 4 balances to weigh the legs of the cows. It was determined that 90% of the cows would have all four legs on the balances during at least two milking sessions. Information is sent from the scale to computers measuring the weight of each leg, it’s position during milking, the number of kicks, how often the cow kicks, and the total time for the milking. A laser distance sensor is used to measure the movement of the cow. The cow’s respiration was also measured. Video cameras also collected data. More information about the cow allows the farmers to keep better track of how each cow is doing and monitor its health.