Bibliography | Home | Download Flash Player to view Robot Demos

As the global population increases at a nonlinear rate and without implicit bound, the global community is immediately faced with crises pertaining to land and food shortages. These shortages exist as a result of aging and inefficient agricultural methodology.

Unfortunately, the current agricultural institution and methodology is not efficient to a degree that supports or accommodates global or general mass demand. Land lies fallow, suffers from nutrient deprivation and commonly does not produce a yield acceptable enough to contribute to the larger picture of global agriculture. If a genuine effort is to be made to increase yields and overall efficiency of the agricultural industry, a massive industrial reform is necessary.

Unlike all other living organisms, humankind has the ability to manipulate its environment. Humans are no longer limited by what was at one time crippling to progress. For example, up until the application of hydroponics, crops were limited to growth in soil. Oftentimes, the soil would become exhausted from overuse, or would not allow the plants to grow to their fullest potential because the soil was lacking in nutrients. It is now viable to produce crops without the use of soil through the process of hydroponics. Through this process one can administer nutrients to plants through alternate means and ensure the most efficient growth.

Humans have the capability to institute a new system of agriculture, one that would revolutionize the global distribution of food, but there is question as to how one would accomplish such. One answer to the current agricultural crisis would be the construction of “agricultural skyscrapers” or "Agtowers". The buildings would employ the use of computer controlled hydroponic growing cycles and specialized robotic systems. Ultimately, facilities such as these can be run all hours of the day and operate independently from the natural growing seasons of the year.

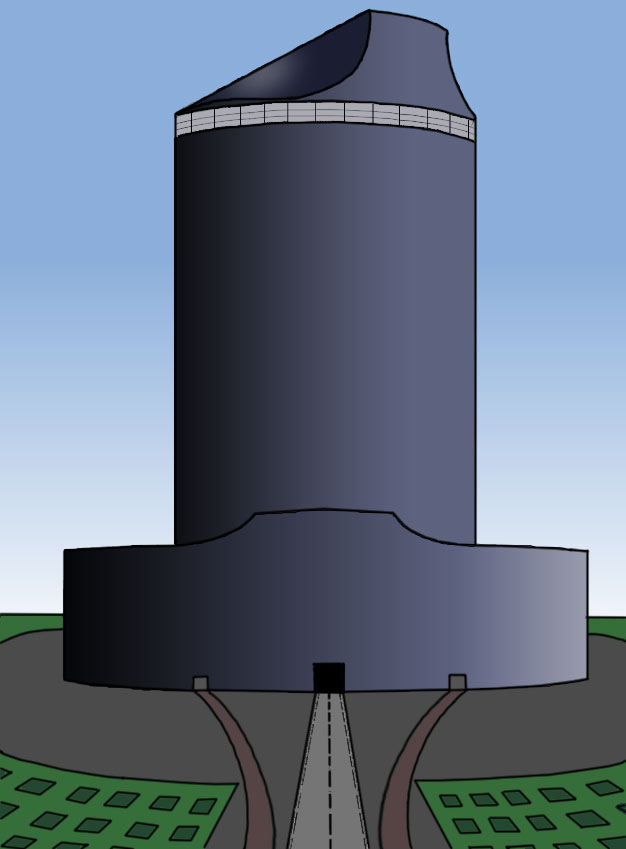

The building would be roughly ninety stories in height and lie on a foundation of about three hundred square feet. The base of the building has a diameter of two hundred feet and height of twenty floors. It is in this part of the building where harvested crops are packaged and shipped. Otherwise, the remainder of the building –a diameter of one hundred feet and height of approximately seventy floors- would primarily serve as the area in which the plants are grown.

The building would be roughly ninety stories in height and lie on a foundation of about three hundred square feet. The base of the building has a diameter of two hundred feet and height of twenty floors. It is in this part of the building where harvested crops are packaged and shipped. Otherwise, the remainder of the building –a diameter of one hundred feet and height of approximately seventy floors- would primarily serve as the area in which the plants are grown.

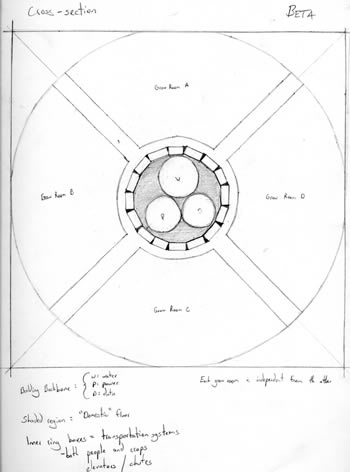

The growing environment would have as little human contact as possible. Ideally, the growing rooms would be governed by computers and interacted with by robots when necessary. Much of the growing process itself can be computerized. Once seeds are planted, the quality and conditioning of the water supply and other factors such as lighting would be run by a feedback-control loop. So matters such as daylight hours, the regulation of nutrients in the water supply, and assessment of the quality of the batch can all be addressed by basic computer input/output logic. Eventually there will come a time for harvesting which would be managed by robots programmed to do such. The harvested crops would then be transported to a storage facility located on a separate floor of the building. A process such as this maintains a sterile environment. In such an environment, the plants are allowed to grow freely with a small probability of contamination. Unfortunately, machines are not self-sustaining nor do they have the capacity to repair themselves. Human interaction will occasionally be necessary in order to address anomalies in production or maintenance. To combat this, the growing floors are designed to contain independent growing “quadrants” which serve as a precaution against contamination. Ultimately each quadrant would be independent from the others leaving the bulk of the crop unharmed if contamination were to occur in one isolated quadrant.

Seeing as though human interaction within the building will be rare, but nevertheless necessary, the topmost floors of the building are reserved as residences. Along with the top floors being reserved as residences, there shall be floors, spaced between each other in intervals of ten floors, which are reserved as temporary storage facilities for harvested plants. It is in these storage facilities where the recently harvested plants shall be prepared for packaging by specialized robots programmed with the necessary functionality. Later, the plants will be transported to the base of the building for packaging and shipping which will be performed by a different set of specialized robots.

Throughout the building there would run a backbone that consists of three main distribution systems: water, power and data. A building such as this would require a great power source. Hopefully, an alternate and more efficient means of generating electricity will have been developed by the time a facility such as this is built. In the meantime, a three-fold strategy will be employed to address energy needs as a supplement to conventional power: hydroelectricity, wind, and solar. As water is pumped through the floors, it will eventually reach the top floors. Once it reaches the top floors, it will be pumped to the center of the structure into the main water line. The main water line will be filled with spinning wheels to capture the energy of the falling water and convert it into electricity. The top of the structure or surrounding land—if available—will be covered in wind turbines or solar panels depending on what the environment is best suited for. Passive solar energy will be captured through the clear outer surface of the structure on the growing floors, and solar collectors will cover any other exposed surface on the outer structure.

Throughout the building there would run a backbone that consists of three main distribution systems: water, power and data. A building such as this would require a great power source. Hopefully, an alternate and more efficient means of generating electricity will have been developed by the time a facility such as this is built. In the meantime, a three-fold strategy will be employed to address energy needs as a supplement to conventional power: hydroelectricity, wind, and solar. As water is pumped through the floors, it will eventually reach the top floors. Once it reaches the top floors, it will be pumped to the center of the structure into the main water line. The main water line will be filled with spinning wheels to capture the energy of the falling water and convert it into electricity. The top of the structure or surrounding land—if available—will be covered in wind turbines or solar panels depending on what the environment is best suited for. Passive solar energy will be captured through the clear outer surface of the structure on the growing floors, and solar collectors will cover any other exposed surface on the outer structure.

The most efficient way to distribute that power is to have each floor in an independent parallel connected to a central source. Along with the distribution of power, it is also necessary to recycle water. In an effort to conserve energy and resources much of the water used in the hydroponic growth of plants will be circulated throughout the floor. Eventually the water on each floor will need to be flushed and recycled, thus making a central water supply necessary. One must not overlook the importance of an adequate data infrastructure in a facility such as this. For a building that is dominated by computers and robots, a network is necessary to monitor and administer tasks. There will also be localized systems that may only span a few floors in the backbone of the building. Along with the distribution of resources a mode of transportation within the building is required. Unfortunately, it may be quite some time before a practical Jetsons-style pneumatic transportation systems is employed, but in the meantime a system of inter-building shafts may be used to transport the harvested crops. The shafts would also have the capacity to double as an elevator system for humans with the need to travel throughout the building.

One of the greatest applications of a facility such as this one is its great versatility. A facility such as this can be erected anywhere, providing that it has an adequate foundation. It can also take advantage of its individual environment. Examples of such locale advantages are the pre-existing transportation systems of metropolitan areas and even the potential solar energy of the desert that can be used to generate electricity. Buildings such as these would produce a yield capable of making a grand contribution to global agriculture. In the most virtuous of applications it could be used to provide foodstuffs for underdeveloped countries unfit to provide for themselves. It would also yield a greater number of crops for the area it occupies when compared with traditional farms. Another important impact is the locality of the produce to the communities these facilities would serve, negating the need for a huge transportation network reliant on fossil fuels.

Ultimately, this design does not state or call for anything profound. It simply suggests the consolidation of existing advanced agricultural techniques and industrial tools into one localized area. A facility that successfully employs the use of next-generation agriculture could possibly prompt a reform in the industry that could eventually accommodate global demand for food and solve many of the food and land shortages that exist today. The rapid growth in population that exists today will not end anytime soon. All that can be done at this present time is to contrive new methods of managing and correcting old and exhausted problems. As advancements in the fields of computers, robotic systems, and agricultural methodology continue to be made, the most logical of ideas is to consolidate them all into one greatly productive and efficient facility.

Download Flash Player to view Robot Demos